RX3 Sidestand Safety Switch

One thing the Cyclone RX3 Duel sport adventure motorcycle lacks is a safety switch on the sidestand to make sure you can't ride off the with sidestand down. If you do ride off with it down the best thing that can happen is a loud scraping, grinding noise as the stand contacts the ground and is flipped into the "up" position. The worst thing that can happen is that you decide to turn left, the stand digs into the ground and you are catapulted from the bike. Neither is desirable, especially the latter! Motorcycle riders have been seriously injured riding with the sidestand down.

How you deal with this issue is a matter for the rider. You can think it will never happen to you and you may be lucky, at least for a while. I don't think I'm that lucky. Alternatively you can deal with it in one of several different ways. I would note that some riders on some motorcycles with sidestand safety switchs fitted decide to remove it. While it could, in theory, cut the engine if you jumped in the air and came down hard enough, I have a great deal of difficulty actually imagining this happening. Even if it did it would probably be an indication of a weak sidestand return spring or a badly adjusted sidestand safety switch and in either case it's something that should be fixed, not bypassed.

If you don't think the sidestand issue is a big deal, see thishttp://www.advrider.com/forums/showthread.php?t=366493

Here's someone who was lucky:

The switch could, I suppose, also fail in the closed position, leaving the bike unable to start, but it's a simple diagnosis and an equally simple fix if you know it's there and you test it. Anyway, if you decide you're not lucky enough to take the risk of never riding off with the sidestand down, the various options are:

- You can install a sidestand operated switch which illuminates a warning light when the sidestand is down. Even if this fails you're no worse off then not having a light fitted!

- You can install a sidestand operated switch which will not allow you to start the engine when the sidestand is down.

- You can install a sidestand operated switch which works in conjunction with the clutch switch and gear position indicator which will cut the engine if the clutch is out AND the bike is in gear AND the sidestand is down.

All of these options require a sidestand operated switch of some kind, so I'll deal with that first. There are two options. The simple option is a mechanical microswitch and the second is a magnetically operated hall effect switch. The advantage of the magnetic switch is that it can be fully waterproofed, at the expense of added complexity. I'll deal with the simple option here, but if you intended to do serious deep mud and water off-roading, a magnetic switch might be preferable. I will add details of a magnetic switch using a hall effect sensor later.

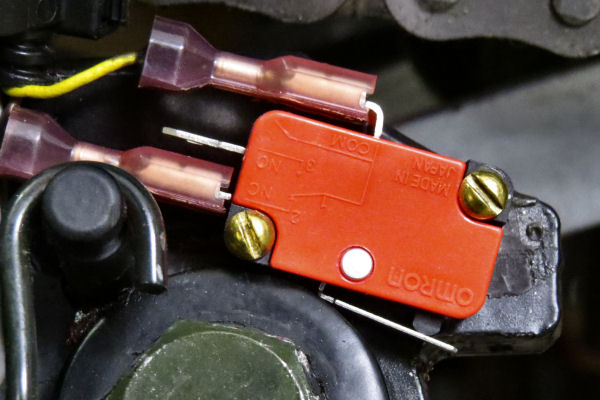

As shown below, all you need to do is attach a microswitch to the sidestand bracket. The switch I used was an Omron V-151-1C25 SPDT microswitch, but any similar microswitch with normally closed contacts could be used.

Using the NC (normally closed) side of the switch, when the sidestand is down the switch is closed. When the sidestand is raised, the lever you can see on the bottom of the switch is depressed and the switch opens. The switch is attached by drilling and tapping two small holes in the side stand bracket. An easier but less reliable method of attachment would be to epoxy it in place.

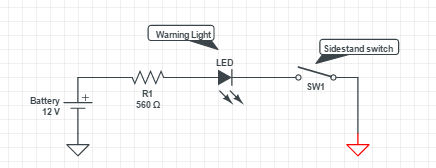

Again sticking with the simple option, this switch can be wired to an LED which can warn the rider when the sidestand is down. The circuit is trivial as shown below:

The LED can be any small (5mm) LED. They draw about 20mA and with a series resistor of around 560 ohms (1/4 watt rating) they can be operated directly from the 12v battery. It will be fine at the typical running voltage of 14.4v too. When the sidestand is down, the switch closes, current flows through the LED which lights up. The connection to the battery should, of course be wired through the ignition system (you can tap it off the the brown +12v wire to the tail light or front position light for example)

All the parts can be obtained via eBay

That's it. You now have a light which warns you when the sidestand is down. Mount it somewhere you can see it. I wired mine to an LED in the sidearm of the instrument cluster as shown below:

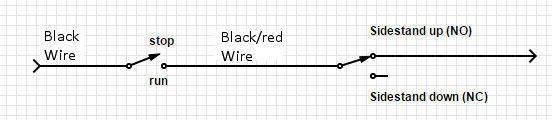

If you want to inhibit starting or running whenever the sidestand is down you can do that pretty easily by tapping into the line from the engine cutoff switch, If you wire the microswitch via the normally open (NO) contact in series with the engine cutoff switch then putting the sidestand down does exactly the same thing as operating the cutoff switch. If the engine is running with the sidestand up and you put the sidestand down it will shut the engine off. If the engine isn't running and the sidestand is down, it will not start.

Using a logic gate and a relay you can build a circuit which allows the bike to be started and run with the sidestand down, but not ridden off. As soon as the clutch is let out with the bike in gear, the engine can be cut off if the sidestand is down. I'll describe that system next. However note that it's

also possible that a simpler solution exists. The Delphi MT05 ECM (engine control module) has a pin (J1-16) which is designated as "Sidestand Switch (low active)" and this may be a pin which, when grounded, prevents the bike from being driven away with the sidestand down, but still allows it to be started and idle in neutral. I don't know this for sure, but it seems quite likely since this is a function available on most motorcycles and so might well be programmed into the ECM. According to the RX3 circuit diagram, this pin is brought out to the diagnostic connector - but in fact it isn't. The spare pin on the diagnostic connector which should have a red/white wire running to it from pin J1-16 of the ECM has no connection at all. If there is a wire running from J1-16 it doesn't go to the diagnostic connector - or anywhere else than I can see. The ECM connectors are sealed so it's very hard to tell what's connected and the wiring loom is tight, has a lot of wires and is heavily insulated so you really can't see what wires are in there without cutting it open, something I'm not quite ready to do yet. If there is a connection to J1-16 (or if one can be made) it could provide a simple route to a sidestand switch that will prevent riding with the sidestand down. I'm looking into this and CSC are helping since they have spare wiring looms which makes it much easier to trace the wires.

UPDATE - According to CSC, pin J1-16 of the ECM has no connection to it. It doesn't even have a blade in the connector plug, so to use this pin you'd have to strip all the silicone insulation off the J1 connector and insert a new blade and wires into position 16, then seal it back up, or somehow thread a wire into the right place to contact the J1-16 pin in the socket on the EMU.

UPDATE

I can confirm that there is no connection to Pin J1-16 on the cyclone RX3, despite what the wiring diagram shows. It is quite difficult to access this pin but I have done so and performed some tests which confirm that if Pin J1-16 is grounded when the bike is in gear and the clutch is out, the engine will stop. This would prevent you from riding with the sidestand down. If you wanted to use this to implement a sidestand safety switch it would be quite simple, the major problem being access to pin J1-16. If you are in any way uncertain about playing with direct connections to the EMU I suggest you don't try it. If you accidentally connect to the wrong pin or accidentally short certain pins together or to ground or the supply voltage, you could do a lot of damage. It's 100% your responsibility. All I can do is report what I found with my RX3. It's possible yours could be different so I accept no liability for anything you do to your bike based on information I report about my bike.

Short of a safe, simple, solution there is a more complex safe solution which I'll describe next

Getting more complex

If you want to prevent the bike from being ridden with the sidestand down, but you want to allow it to be started and to idle in neutral with the sidestand down, things get slightly more complicated. You have to look at the state of the clutch switch, the state of the gear position indicator and the state of the sidestand switch. You want the engine to stop (or refuse to start) only when the bike is in gear AND the clutch is released AND the sidestand is down.

When the clutch is released AND the bike is in gear, the light purple wire going to the clutch switch is at around 4.5v (a logical 1), so we already have a signal that tells us the bike is in gear and the clutch has been released. NOTE - this is a logic signal connected directly to the ECU and cannot supply any appreciable current. It can only be used as an input to another logic gate or PIC controller input. It can't be used to power a relay or even light an LED. If you connect it to the battery (12v) you will fry the ECU.

What we need is to then look at the sidestand switch. If the sidestand is up, all is well, but if the sidestand is down then we want to stop the engine. There are a number of ways in which this could be done. One would be by using an AND gate and transistor switch. Another might be to use the logical 1 already generated (4.5v), feed it through a sidestand switch and use it to trigger a transistor switch which operated a relay in series with the engine stop switch. Just some ideas. When I put one of them into practice, I'll add the details here.

Details

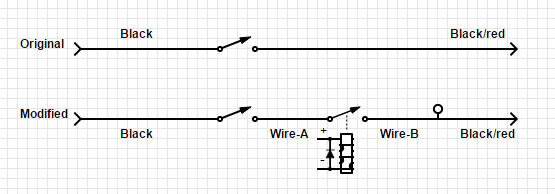

I decided to do this the 100% safe way. It may not be the most elegant and it may not use the munimum number of components, but it won't fry the ECU either! First I wired a relay module in series with the kill switch. That means inserting a relay in the Black wire with the red stripe that comes out of the switch assembly on the right grip. Problem is that TWO black wires with a red stripe come out of that assembly. The Wiring schematic is wrong. Black wires with a red stripe to to both the kill switch and the starter switch (which is supposed to have a red wire with a yellow stripe according to the wiring diagram.

The easiest way to get the right wire is to take the right hand switch assembly apart (two screws)and remove the kill switch (3 screws). Remove the black wire with the red stripe from the kill switch and a attach it to a long wires I'll call "wire A". Then solder a similar length of wire (wire "B") to the terminal on the switch that the black wires with a red stripe was soldered to. If the far end of wire "A" is connected to the far end of wire "B", everything will work just as it did before. If the two wires are disconnected it's just like hitting the kill switch. What we will do is connect a relay between these wires which is normally closed. In that position everything works just like it did originally. However if we power up the relay, the circuit will break and the engine will stop.

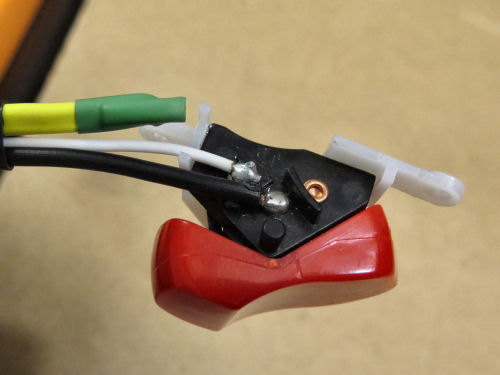

Here's what the wiring inside the right hand side switch assembly looks like after modification:

The white wire is attached to the terminal that the black wire with a red stripe was originally attached to. The black wire has not been touched. The original black wire with red stripe is attached to another length of wire and insulated with the yellow and green shrink tubes. Both wires are just soldered to the switch terminals. Relying on a soldered joint for mechanical strength is not a recommended practice, but that's how it was done by Zongshen and that's how I've left it. The wires are pretty firmly clamped in position inside the switch assembly so the soldered connections will probably never cause a problem.

So here's the circuit so far:

Now all we have to do is combine the existing logic level 1 signal from the clutch and neutral switch with a signal from the sidestand switch and use the result of that combination to open the relay only when the bike is in gear, the sidestand is down and the clutch is released. Easy!